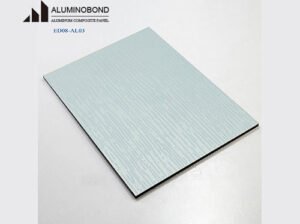

Brushed Aluminum Composite Panel has strong anti-corrosion performance, surface color bright, uniform and durable, is a green decorative materials.

Basic Info

| Surface coating thickness | 30um |

| Aluminum alloy sheet thickness | 0.50×0.50mm, 0.40×0.40mm, 0.30×0.30mm, 0.21×0.21mm, 0.15×0.15mm, 0.12mmx0.12mm, 0.10mmx0.10mm |

| Thickness | 2mm, 3mm, 4mm, 5mm, 6mm |

| Width | 1000mm , 1220mm (regular), 1250mm, 1300mm, 1500mm, 1550mm |

| Length | 2440mm to 6000mm |

| Standard size | 1220 x 2440mm |

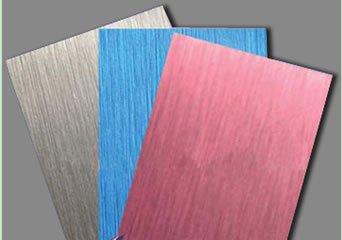

| Normal color | 60 colors for Normal aluminum composite panel 7 colors for granite grain panel |

| Non-standard sizes and special colors are available, according to customers’ requests | |

Description of Brushed Aluminum Composite Panel

Brushed Aluminum Composite Panel’s structure is composed of two aluminum sheets couple unto polyethylene material core. The two aluminum sheets have properties of corrosion resistant and when bonded with the polyethylene core produces the product that is to be finalized through brushing which we will take about later in the article. Nevertheless brushed aluminum composite panels are great products when it comes to the fulfillment of individual customers.

Brushed Aluminum Composite Panel’s structure is composed of two aluminum sheets couple unto polyethylene material core. The two aluminum sheets have properties of corrosion resistant and when bonded with the polyethylene core produces the product that is to be finalized through brushing which we will take about later in the article. Nevertheless brushed aluminum composite panels are great products when it comes to the fulfillment of individual customers.

Brushed coated aluminum panels have been in high demand over the last few years, this is because of the fact that brushed coated panels present quite diverse options with consistent features. The most common applications of brushed coated panels would be the usage in wall boards & ceilings for tunnels, billboards & signs, used in manufacturing of bodies of cars & ships, interior and external wall cladding. One of the biggest advantages of brushed panels is the fact that they come out in a variety of colors for this sole reason. The usage of brushed panels in kitchens and rooms is also common.

Features

Sandwich panel construction techniques have experienced considerable development in the last 40 years. Previously, sandwich panels were considered products suitable only for functional constructions and industrial buildings. However, their good insulation characteristics, their versatility, quality and appealing visual appearance, have resulted in a growing and widespread use of the panels across a huge variety of buildings. What features does the Aluminum Composite Panel have?

- Super peeling strength.

- Excellent surface flatness and smoothness.

- Superior weather, corrosion, pollutant resistance.

- Even coating, various colors.

- Fireproof, excellent heat and sound insulation.

- Superior impact resistance.

- Lightweight and easy to process.

- Easy to maintain, self-clean.

Our advantage

- Products are manufactured with the high-purity aluminum sheets and high-quality polyethylene materials, with the combination of advanced science and technology and high-precision devices.

- The company possesses 7 production lines for aluminum composite panels whose annual output is 12 million square meters.

- Aluminobond is renowned for its high quality and cost-effective aluminum composite panel. The product catalogue of us is one of the most complete product lineups in the industry.

- Various design, colors and textures of aluminum composite panel is available, Aluminobond lays a lot of emphasis on R & D, efficiency and consistent production.

Aluminobond Qualification

- Registered with a capital of 10 million RMB, we have a dedicated staff of over 1000 employees, with annual revenues of 400 million RMB.

- We have passed the rigorous inspections of the National building materials testing center, and ISO9001 certificate, CE certificate, ASTM standards certificate; SGS certificate is also available at Aluminobond.

- The Chinese Construction Center designated us as a “Triple-A Enterprise” for national construction systems and we are recognized as a “Top 10 Quality Brand” in the domestic building.